In December 2020, version 1.0.2 of IBM Engineering Lifecycle Management Automotive Compliance (ELM AC) will be released. ELM AC helps automotive engineering organisations to setup their IBM Engineering tools according to automotive standards. We are also seeing interest from clients in other industries, since much of the thinking and workflow around compliance is common. The first version of ELM AC was released in December 2019 and focused on supporting Automotive SPICE process groups. The new version extends ELM AC for key aspects around functional safety (ISO 26262).

An engineering dashboard with a dedicated view for safety

In version 1.0.2, ELM AC was extended with a dashboard tab to monitor status and progress of safety work items and work products. The reporting package was enhanced with dedicated safety reports and filters for safety. The complete reporting package includes over 100 reports that give insights into planning, testing status, requirements consistency and completeness, status of problems, change requests, reviews and findings.

With the extended and refined reporting package of ELM AC v1.0.2, engineering teams gain increased transparency for safety-related work. With reports for safety readiness, teams can make educated decisions whether they want to go forward with a release or milestone. Differentiating between safety and QM (non-safety) aspects can be helpful to understand impact of an early release and to thus help to respect safety culture.

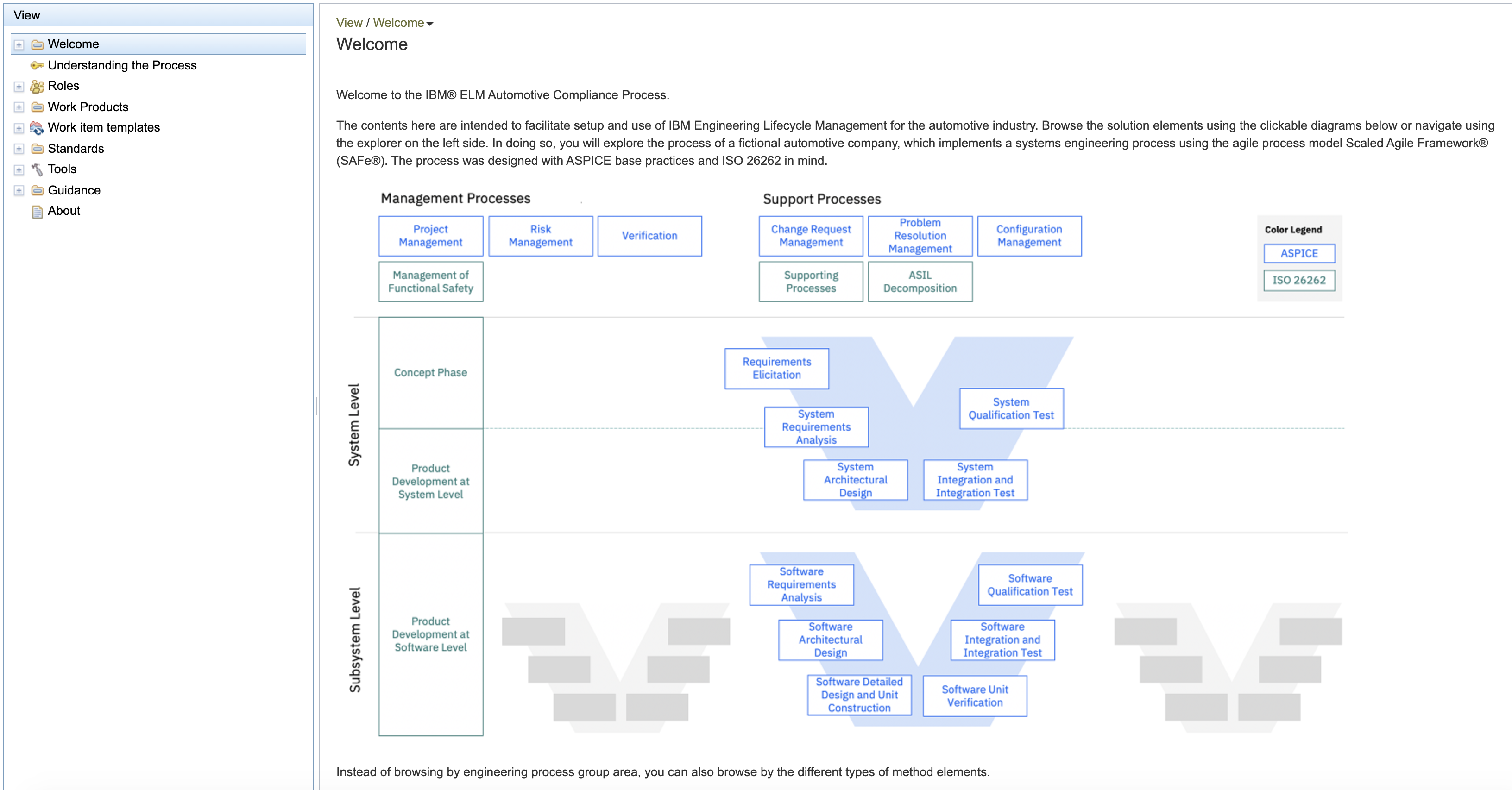

The ELM AC process content was extended with process description and an ISO 26262 mapping

The Method Composer (MEC) process content includes descriptions for roles, process steps and work products. ELM AC v1.0.2 extends the process content in two ways: 1) The solution mapping and process descriptions were extended for ISO 26262. The corresponding chapters are displayed in teal color in the screenshot of the AC process portal landing page below. 2) ELM AC v1.0.2 also contains a new template to refine the process content using the Method Composer web authoring capability in DOORS Next.

With these extensions to the Method Composer Process content, IBM ELM Automotive Compliance users understand what and how ELM AC content helps them to comply with ISO 26262. The project template to tailor the process description, allows users to tailor the IBM ELM Automotive Compliance process for 1) their organisation and 2) for each department. Managing this process tailoring is a key aspect to achieve ASPICE Level 3 compliance.

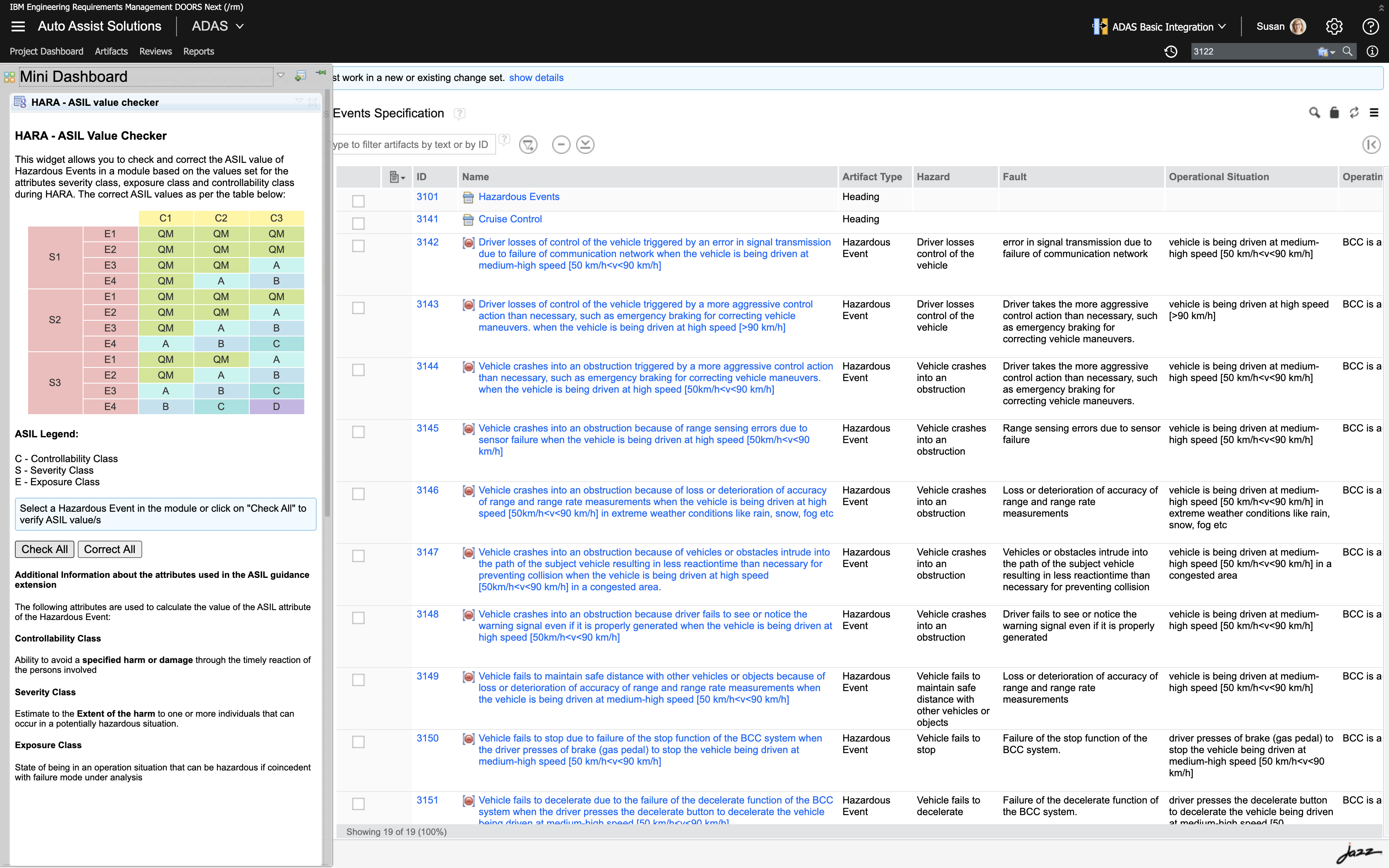

ELM AC now supports safety concept and requirements phase with a HARA template and ASIL checker

ELM Automotive Compliance was extended to support hazard and risk analysis (HARA) within DOORS Next. The requirements management template now includes custom attributes to capture safety elements using vocabulary and structure as defined by ISO 26262 (e. g. Item Definition, Hazardous Events, Safety Goals, Safety Requirements). The safety levels (ASIL) of requirements can be evaluated using an automised value checker which is also provided as part of the Automotive Compliance offering.

By relying on the pre-defined template for HARA, engineers can save time when performing safety analysis. Managing their analysis in DOORS Next allows teams to benefit from version control and audit trails to handle collaboration. Since DOORS Next allows linking for every artefact, the results of the safety analysis become part of the engineering data set and can be better considered in impact analysis as needed for evaluation of change requests.

ELM AC now supports ASIL Decomposition with dedicated attributes and reports

Safety goals are implemented by functional and technical safety requirements. ISO 26262 allows engineers to decompose safety levels when defining lower level requirements. This means, parts of a systems can be implemented with lower rigour. When decomposing safety levels, the decomposed requirements have to be implemented independently (coexistence criteria). In ELM AC v1.0.2, the decomposition of safety requirements is supported with dedicated ASIL attributes following the ISO 26262 standard notation. Moreover, ELM Automotive Compliance provides reports to detect violations against decomposition coexistence criteria.

With these extensions, engineers are supported to perform ASIL decomposition in a standardised and a safe way. The included reports help to detect and resolve dependencies between safety-critical and non-safety-critical components.

IBM ELM AC is now available as token license

With 1.0.2, ELM AC can be purchased as token license. In previous versions, ELM AC was only available as Floating and Authorised license. Customers who plan to use ELM AC with ELM 7.0.2 or later can use IBM ELM Automotive Compliance as token license. The license is specific to ELM Automotive Compliance and does not entail access to any other IBM Engineering product. By offering ELM Automotive Compliance as token license, customers benefit from automised compliance to the ELM AC licensing terms. Also, customers are able to later report on their license usage. Floating and Authorised licenses continue to be valid licensing options. We recommend reaching out to your local sales representative for more detailed information.

AC now supports performing and tracking of ISO 26262 confirmation reviews

To comply with ISO 26262, companies have to perform confirmation reviews for key safety work products. ISO 26262 prescribes for which work products confirmation review have to be performed and how independent the reviewer has to be. In version v1.0.2, IBM ELM Automotive Compliance was extended with templates to plan and perform confirmation reviews. ELM AC v.1.0.2 contains a work item template which automises the creation of all required confirmation review. ELM AC also provides reports to track status of confirmation reviews as well as corresponding checklists and findings.

With the confirmation review approach introduced in ELM Automotive Compliance, engineering teams gain a systematic, tool-guided process to capture and perform confirmation reviews. Thus, engineering teams are enabled to track and monitor the status of confirmation reviews, understand the required level of independence, who performs them and what findings need to be addressed

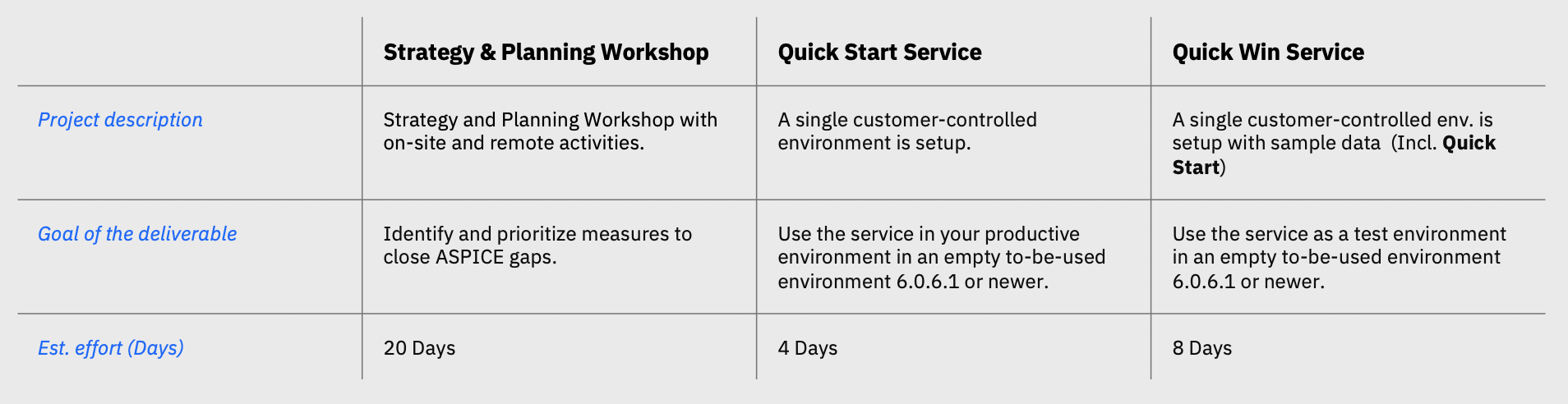

IBM offers tailor-made service offering to adopt ELM Automotive Compliance

You can get ELM AC installed and setup in less than a week of effort. IBM also offers services that includes ASPICE assessments and a detailed analysis of your current tool landscape. As a result of this project, you know exactly where you stand and how can reach your compliance goals most efficient. Please reach out to your local IBM Expert Labs (formerly IBM Lab Services) representative or Judith Leick (jleick@de.ibm.com) to learn more about these service offerings.

External parties provide additional content for IBM Engineering like expert checklists and tool qualification

IBM ELM Automotive Compliance helps customers to tailor IBM Engineering tools for automotive standards. There is additional content available to help customers with compliance for ISO 26262 from two different parties.

Kugler Maag Cie is a consultancy focused on regulated systems and software engineering development. For the confirmation review process introduced in ELM AC v1.0.2, the company offers expert checklists that can be used to validate work products as required by ISO 26262. The checklists can be imported and used in IBM ELM AC. ELM AC provides reports to track status and exceptions in these checklists. We recommend to visit the Kugler Maag Cie website (external link) and to reach out to them directly to learn more.

Validas is a company specialised on tool validation and qualification. The company offers solutions to automise the process of classifying, validating and qualifying software tools. Validas now offers tool qualification kits for IBM Engineering products. The company offers two different sets of products:

- Validas 26262 QKit for IBM DOORS

- Validas 26262 QKit for IBM ELM

We recommend to visit the Validas websites (external link) and reach out to them directly for more information.

In context of ISO 26262, it is important to note that there is also a dedicated ISO 26262 QKit for IBM Rhapsody focused on code generation and testing with Rhapsody TestConductor AddOn. You can find the corresponding validation suites and guidance in IBM knowledge center.

[…] There are many other improvements both large and small; you can read all the New & Noteworthy entries for the full scoop. Automotive Compliance 1.0.2 is also being released, featuring improved support for functional safety and ISO 26262 (read more here). […]